Time:2020-06-04 Hot:5001 Return

There are five methods for cable prediction:

1. Three-point type;

2. Magnetic flux method;

3. Cable pre-tension dynamometer;

4. Strain gauge: Mainly used for laboratory teaching, it is not convenient to use on site.

5. Nanometer: It is difficult to buy at present, it belongs to the concept stage.

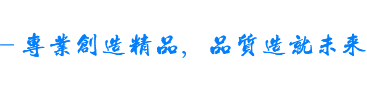

1. Three-point type:

A series of data is obtained in the laboratory in advance according to the magnitude of the force-the relationship between cable tension and thrust. This process is called the calibration of the dynamometer, and then the pre-tightening force of the cable is reversed according to the data curve. In this method, if the surface of the cable has burrs, bumps or slippage, it will affect the force, so the error is relatively large.

2. Magnetic flux method:

It is based on the principle of magnetic flux, the cross-sectional area of the cable will be reduced when it is pre-tensioned, according to the reduced

The area is used to judge the pretension of the cable. The cable is made up of many steel wires, each

The cross-sectional areas of the steel wires are not completely equal, resulting in the cross-sectional areas of the cables are not completely equal, so the magnetic

The general measurement also has a large error.

3. Cable pre-tightening force gauge:

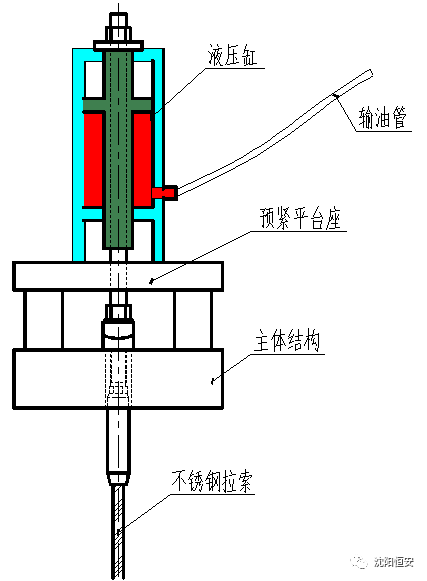

The pre-tension dynamometer for pre-stressed structure is a patent developed by our company. It puts the cable pre-tension dynamometer on the outside of the two decorative nuts at the adjustment end of the cable, and then pre-tensions and pressurizes the cable. The pressure gauge The force value of the cable will be displayed.

This method is simple to test and accurate in readings. It has been applied in many cable projects such as the Inner Mongolia Grand Theater, Shenyang Olympic Sports, the second phase of the Capital Library, the Fangzhi Pavilion, and Lutai Convention and Exhibition Center.

It is difficult to manually tension a large-diameter cable. This method has the most obvious advantage in solving large-diameter cable tension and force measurement.

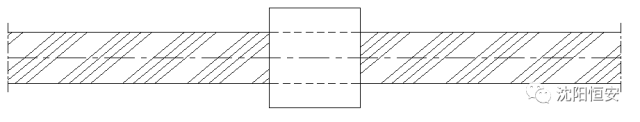

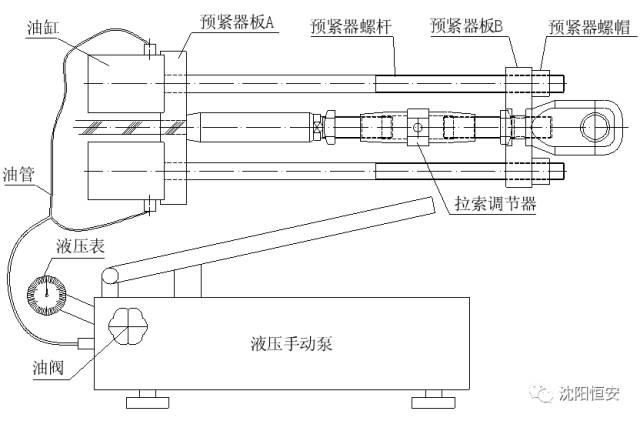

Schematic diagram of cable pretension dynamometer

The pre-tension dynamometer for pre-stressed structure is composed of a special hydraulic cylinder, oil pump and pressure gauge. The device is fixed on the lock nuts that have been loosened at both ends of the pre-tensioning pipe. The oil pump is pressurized, the piston in the cylinder moves, and the piston drives the cable to tighten, and the pre-tightening force is displayed on the pressure gauge until it reaches the preset value. Tighten the pre-tightening sleeve and remove the pre-tensioner after releasing the pressure.

The mechanism is light, easy to use, accurate in measurement, and realizes both preload and force measurement.

The cable pre-tensioning force measuring device has applied for a national patent, patent number: ZL2004 2003 1177.X.

Because the original patented structure has the influence of eccentric force, especially when pre-tightening a large diameter cable, the eccentric force is large, the equipment is easy to bend, and the accuracy of the pre-tightening force measurement is affected. Therefore, we have made improvements and now use double cylinders. The pretensioner pretensions the cable.

The dual-cylinder pretensioner adopts the principle of the original patented structure, which eliminates the influence of eccentric force, ensures that the pretension force measurement of the structure is more accurate, and the equipment is not easily damaged.

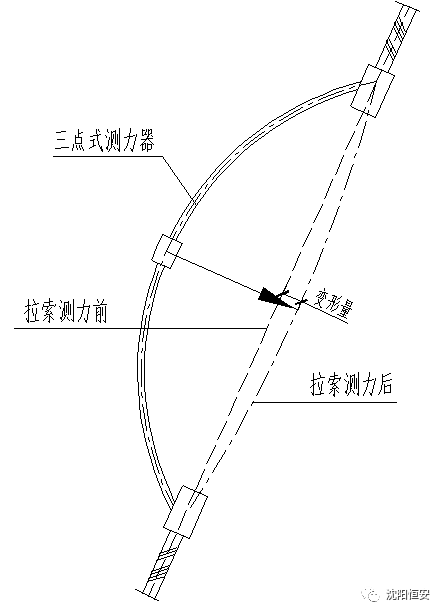

Schematic diagram of dual-cylinder cable pre-tightening force gauge

Cable tension pretensioner without regulator:

Schematic diagram of tension gauge without adjusting end

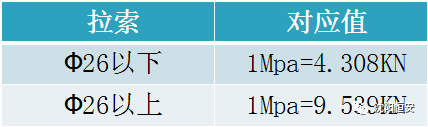

Corresponding value of cable preload and hydraulic gauge

024-24340395

024-24328251

No. 601, Tongcheng Road,

Hunnan New District, Shenyang

E-mail:sy_hengan@163.com

Fax:0086-24-24328251

Mobile

All rights reserved 2020 the official website of

Xingye Machinery Factory liaoicp no.05006069-1